Assemble various high-voltage cabinets of different functions and sizes to improve mobility efficiency.

The original production process of the customer: The installation of each electrical cabinet at each workstation, as well as the adjacent assembly and debugging, are all completed through aerial cranes, which have a large workload and low efficiency every day.

After using the air cushion vehicle: the air cushion vehicle can be lifted in one go. When moving and assembling adjacent workstations, the suspension is no longer used, but the air cushion vehicle can be moved as a whole in one go, which increases the efficiency of movement, increases production capacity, and reduces lifting accidents.

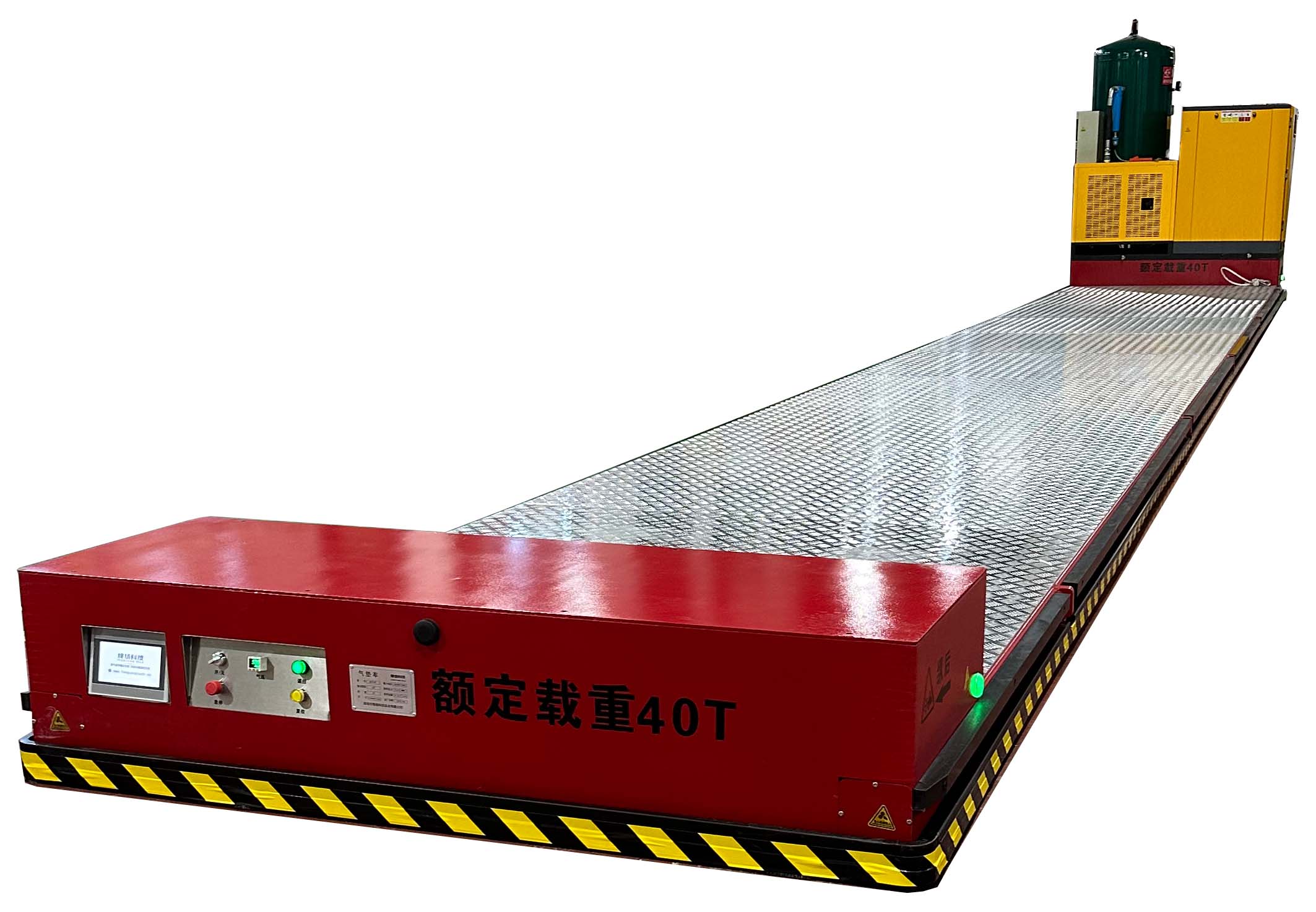

According to customer application requirements, Fengyang Technology has designed two three air cushion vehicles for production use, including two air cushion vehicles with a length of 17 meters and a load capacity of 40 tons (15 meters long and 0.19 meters high in the load area), and one air cushion vehicle with a length of 12 meters and a load capacity of 30 tons (10 meters long and 0.19 meters high in the load area), with its own air source (three-phase five wire 380v, 40kw).

The customer sorted out the original operation process based on the air cushion vehicle provided by Fengyang Technology. Basically, the high-voltage electrical cabinets of various functional and small components were moved separately to the 10KV and 220KV detection points by a crane. Six or more workers spent more than half a day assembling and splicing them, and after testing, the assembly was released and each component was lifted back separately, which was time-consuming and less efficient compared to air cushion vehicles.

After using the air cushion vehicle customized by Fengyang Technology, the customer assembles the high-voltage electrical cabinet and splices the electrical cabinets on the air cushion vehicle in the production area. After assembly, the air cushion vehicle does not need to be lifted and moved to the inspection area as a whole, realizing that one group of high-voltage electrical cabinets can be moved to the inspection line on another air cushion vehicle for inspection while assembling. This achieves a production line operation of simultaneous production and inspection, reduces the number of lifting operations, further improves the safety of factory production, and enhances the efficiency of the entire production line.